As industries and communities strive to find sustainable cooling solutions that meet both their operational needs and environmental responsibilities, Mirai Intex’s Air Cycle Technology emerges as a leading innovation. To explore further about Mirai Intex and its revolutionary technologies, visit the company’s website. The drive to reduce the ecological footprint of refrigeration systems is more crucial than ever, especially in light of stringent global regulations and the rising demand for eco-friendly technologies.

Mirai Intex: Pioneering Air Cycle Cooling Technology

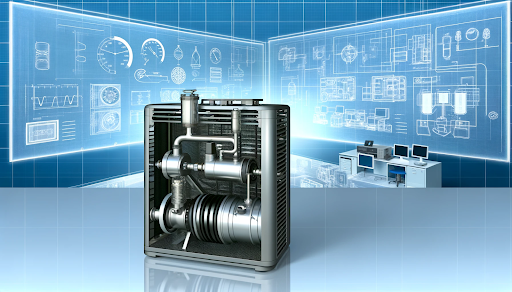

Mirai Intex, based in the Czech Republic, is at the forefront of developing air cycle technology that leverages the natural properties of air, offering a viable alternative to harmful refrigerants. By utilizing the principles of air compression and expansion, Mirai Intex’s systems achieve ultra-low temperatures, crucial for various industrial applications, without compromising on safety or efficiency.

Core Technology Explained

The essence of Mirai Intex’s technology lies in its simplicity and brilliance. Air cycle systems function by compressing air, which heats it up, and then allowing it to expand and cool down. This process can be precisely controlled to provide cooling or heating as needed. Importantly, the integration of components such as the turboexpander and compressor on the same shaft enhances the system’s efficiency by up to 30% compared to traditional systems.

Environmental and Operational Benefits

Mirai Intex’s technology does not rely on chemical refrigerants, which are often linked to ozone depletion and global warming potential. Instead, it uses atmospheric air (R729), which has zero Global Warming Potential (GWP) and does not fall under F-gas regulations. This not only ensures compliance with international environmental agreements but also reduces the risks associated with refrigerant leakage and disposal.

The air cycle systems designed by Mirai Intex are distinguished by their safety features. They operate at low gauge pressures and do not involve high-pressure components, minimizing risk factors and maintenance requirements. These systems are also characterized by their quiet operation and lack of vibrations, making them suitable for various settings, including medical and food storage applications.

Key Features and Advantages:

- Energy Efficiency: Utilizing the same shaft for the turboexpander and compressor significantly cuts energy usage.

- Environmental Safety: Uses natural air, eliminating the use of harmful refrigerants and associated risks.

Applications and Innovations

Mirai Intex’s refrigeration solutions find applications across a broad spectrum of industries, from biomedical storage to pharmaceuticals, where precise temperature control is critical. The company’s recent innovations include the Mirai XS CRYO system, specifically designed for the semiconductor industry, capable of achieving temperatures from -120°C to +50°C. This system highlights Mirai’s commitment to addressing the unique challenges of high-tech industries.

Recent Milestones in Innovation:

- Mirai XS CRYO: Designed for semiconductor manufacturing with precise temperature controls.

- Sustainable Collaborations: Partnerships with industries to integrate eco-friendly refrigeration technologies.

Conclusion

Mirai Intex’s air cycle technology not only offers a sustainable alternative to traditional cooling methods but also sets a new standard in the refrigeration sector for energy efficiency and environmental stewardship. As the industry moves towards more sustainable practices, Mirai Intex’s innovations are likely to play a significant role in shaping future cooling solutions.

In an era where environmental impact is a major consideration for industries worldwide, Mirai Intex’s air cycle technology represents a significant step forward in achieving a cooler, more sustainable tomorrow.